Made in China Safeguards Central Asian Energy | Lianggu Valves Join Uzbekistan Sukhandarya 1600 MW Combined Cycle Power Plant Project

2025-09-15

A modern 1600 MW combined-cycle gas power plant is rising in the Surkhandarya region of southern Uzbekistan. This project is not only the country’s largest single-unit combined-cycle power station to date, but also a landmark initiative to ease local power shortages and drive the green transformation of its energy structure.

As a key project under the Belt and Road energy cooperation, the Surkhandarya project adopts an advanced combined-cycle design and is scheduled to enter commercial operation in 2027. With a focus on high thermal efficiency and lower unit emissions, it will provide stable baseload capacity to Uzbekistan’s national grid. The project is designed to integrate high-efficiency gas turbines with heat recovery steam generators, targeting a system efficiency of over 60%

Lianggu Valves Deliver “Key Components” to Major Power Plants Worldwide

Power station valves may appear to be just “parts,” but in reality, they are vital components that safeguard unit safety, ensure operational efficiency, and extend equipment service life. Lianggu Valve Group understands this responsibility deeply — from material selection and precision casting to seat fitting and sealing tests, every step directly impacts leakage control, start-stop reliability, and maintenance cycles.

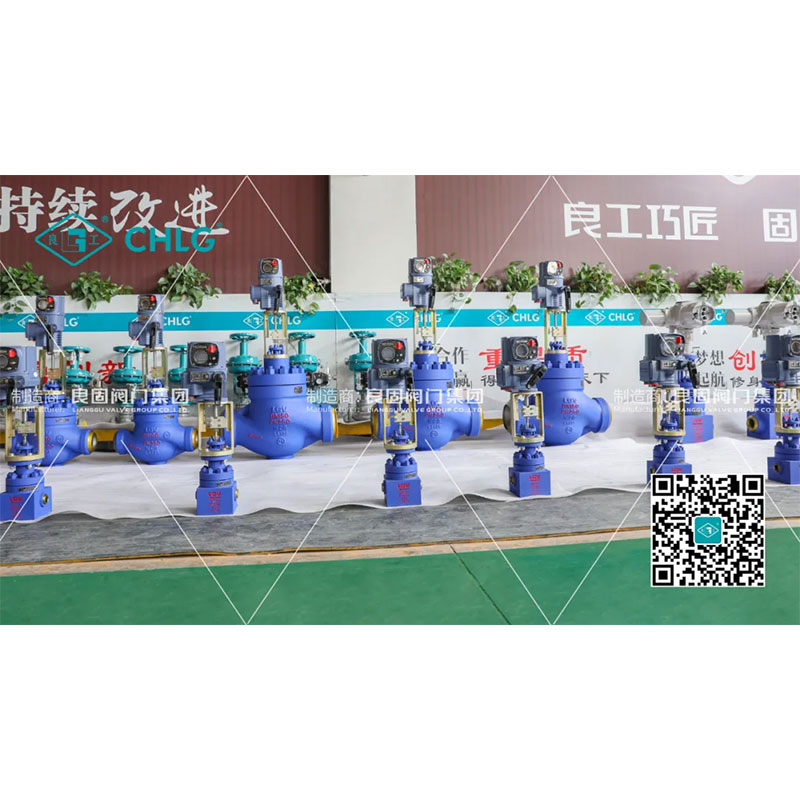

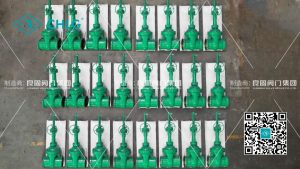

We are honored to supply a batch of critical system valves for the Surkhandarya 1600 MW power plant, which are now ready for deployment. This not only reflects the trust in Lianggu’s quality, delivery, and service capabilities, but also stands as another testament to Chinese manufacturing contributing to overseas engineering projects.

The Value We Bring to the Project

Reliability First: For demanding conditions such as high temperature, high pressure, and frequent start-stop cycles, we adopt high-strength alloys and rigorous heat treatment processes to ensure long-term stable valve performance.

Process and Testing: Comprehensive CNC machining, along with coordinate measuring, ultrasonic inspection, and pressure testing, guarantees that every valve meets both power plant acceptance standards and international specifications.

Delivery and Assurance: Production and testing are carried out strictly in accordance with international standards. Complete technical documentation and records are provided to ensure seamless integration into the project system.

Customization Capability: We deliver tailored valve solutions for critical applications, including steam systems adjacent to turbines, bypass systems around heat recovery boilers, as well as gas-side and main steam systems

Experience and Confidence in International Collaboration

The Surkhandarya project brings together international turbine manufacturers, EPC contractors, and equipment suppliers from multiple countries, operating under stringent engineering management standards and rigorous acceptance procedures.

Lianggu Valve Group has accumulated extensive experience in project management, quality control, and cross-border logistics through its participation in multiple international power and industrial projects. These capabilities ensure that in large-scale energy projects, Lianggu not only delivers outstanding product quality but also provides seamless cooperation and support.